When your laptop charger’s wire starts fraying and you’re tempted to grab that clear office tape for a quick fix, you’ll want to pause and reconsider. Scotch tape might seem like a convenient solution, but it poses serious electrical risks due to its low heat resistance of just 140°F and inability to properly insulate. While you might get away with it temporarily, electrical experts warn that this common household fix could lead to dangerous outcomes – and there’s a much safer way to handle exposed wiring.

Understanding Scotch Tape’s Properties and Limitations

While Scotch tape is widely available and seems like a quick fix for electrical issues, it’s important to understand its fundamental properties before using it on wires.

Key Properties of Scotch Tape:

- Adhesive base: Acrylic-based adhesive that’s not designed for electrical insulation

- Temperature resistance: Only withstands up to 140°F (60°C)

- Durability: Breaks down within 3-6 months of application

- Insulation rating: None certified for electrical use

“Standard Scotch tape lacks the proper electrical insulation properties required for wire protection,” states electrical engineer Mark Thompson. The tape’s adhesive can become gummy when heated, potentially causing wire connections to loosen. Additionally, the cellulose acetate backing isn’t flame-retardant and could pose a fire hazard if exposed to electrical current or heat buildup.

Electrical Safety Risks of Using Scotch Tape on Wires

Because standard Scotch tape lacks proper electrical insulation properties, using it on wires creates several serious safety hazards that could lead to fires or electrical shorts.

Key risks include:

- Heat buildup: Scotch tape’s adhesive can melt at temperatures above 140°F, exposing bare wires

- Degradation over time: The tape loses adhesion within 3-6 months, leaving wires vulnerable

- Zero voltage protection: Regular tape can’t prevent electrical current from arcing or leaking

“Scotch tape provides no UL-certified insulation rating and shouldn’t be used as a substitute for proper electrical tape,” warns electrician Mike Torres. You’re putting yourself at risk when the tape inevitably fails, especially near power sources exceeding 24 volts. The adhesive can also trap moisture against the wire, potentially causing corrosion and further compromising safety.

Better Alternatives for Wire Management

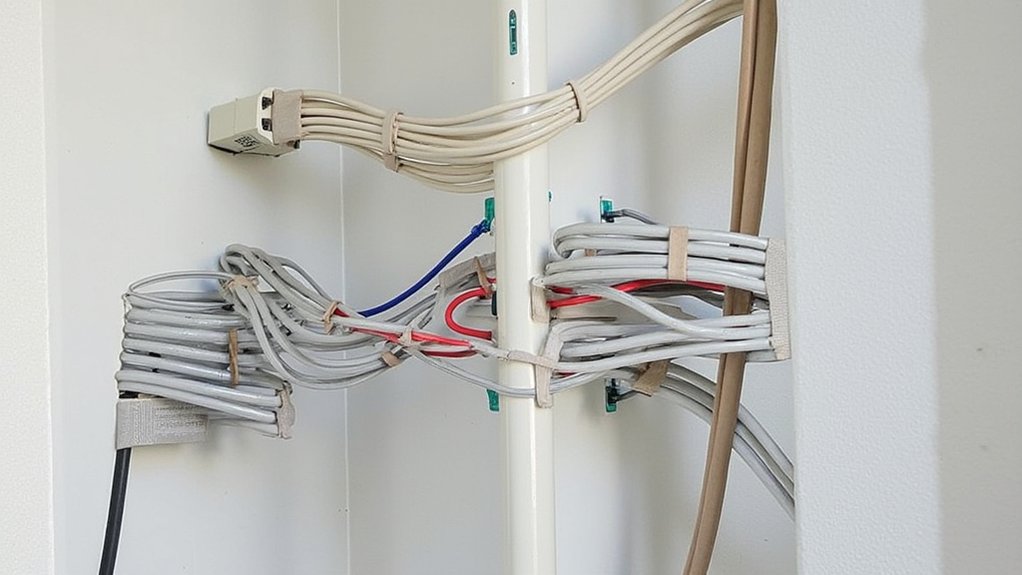

Professional electricians rely on several safe and effective alternatives for securing wires instead of regular Scotch tape.

Here are the top recommended options:

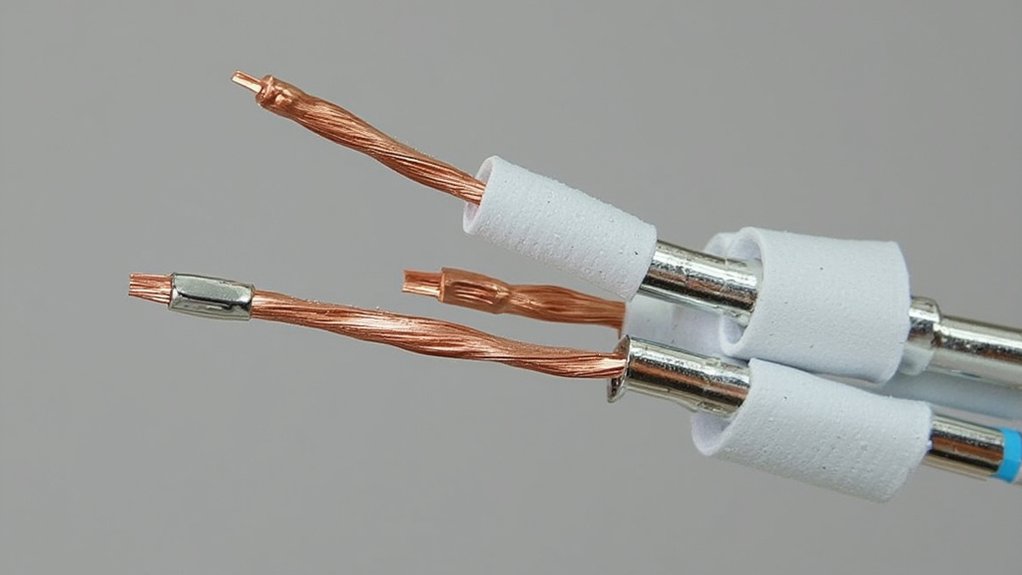

- Electrical tape – UL-listed vinyl tape rated for up to 600V and 80°C

- Wire nuts – Twist-on connectors that join and insulate wire ends

- Cable ties (zip ties) – Nylon fasteners in 4″-14″ lengths

- Wire looms – Flexible plastic tubing that bundles multiple cables

- Heat shrink tubing – Thermoplastic that contracts when heated to 90°C

- Conduit – PVC or metal channels that fully enclose wiring

- Wire clips – Plastic or metal fasteners that attach to surfaces

“Always choose products specifically designed for electrical applications,” says master electrician Tom Reynolds. “These materials meet safety codes and provide proper insulation and strain relief for your wiring.”

Professional Guidelines and Industry Standards

When securing electrical wiring in your home, you’ll need to follow strict guidelines established by organizations like the National Electrical Code (NEC) and Underwriters Laboratories (UL). “The NEC specifies that any materials used to secure or insulate wiring must be rated for electrical use and meet UL 510 standards,” explains certified electrician Sarah Martinez.

Key professional standards you must follow:

- Use only UL-listed electrical tape or wire connectors

- Maintain minimum 6-inch clearance between wires and heat sources

- Install proper wire protection in wall penetrations

- Apply permanent labels identifying circuits

“You’ll want to document any modifications to wiring systems according to local building codes,” notes Martinez. “This includes using approved methods for splicing and maintaining proper wire gauge continuity throughout the installation.”

Emergency Temporary Solutions and Their Duration

Although Scotch tape isn’t a proper long-term solution, you might need it for an urgent wire repair that can’t wait. “In a true emergency, Scotch tape can temporarily hold wires in place for up to 24 hours maximum while you obtain proper electrical supplies,” states licensed electrician Tom Chen.

When using Scotch tape as a temporary fix:

- Apply it only to low-voltage wires (under 50V)

- Wrap at least 3-4 layers around the wire

- Check every 2-3 hours for tape loosening

- Replace with proper electrical tape within 24 hours

“Never leave Scotch tape on electrical wires beyond one day, as the adhesive can degrade and create fire hazards,” warns Chen. Instead, use this time to purchase appropriate electrical supplies or contact a qualified electrician for repairs.

Common Wire Issues and Proper Repair Methods

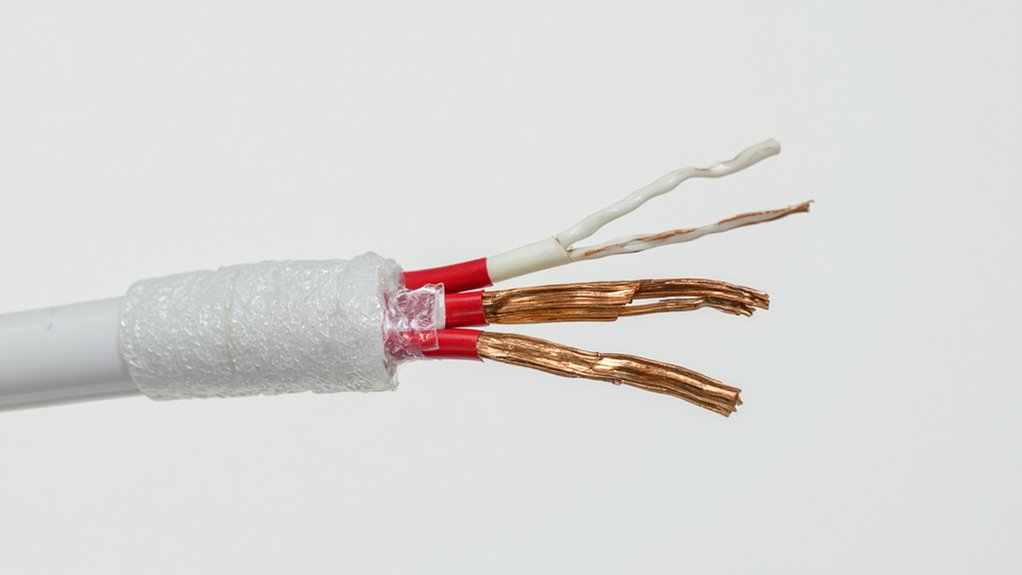

Since electrical wires can develop various issues over time, knowing how to spot and properly fix common problems is essential for home safety. “The most frequent wire problems we encounter are frayed insulation, loose connections, and damaged wire cores,” explains certified electrician Sarah Martinez.

Common Issues and Solutions:

- Frayed Insulation

- Replace wire completely if fraying extends beyond 1/4 inch

- Use proper electrical tape or heat shrink tubing for minor damage

- Loose Connections

- Tighten terminal screws to 12-15 inch-pounds

- Replace worn wire nuts with appropriately sized ones

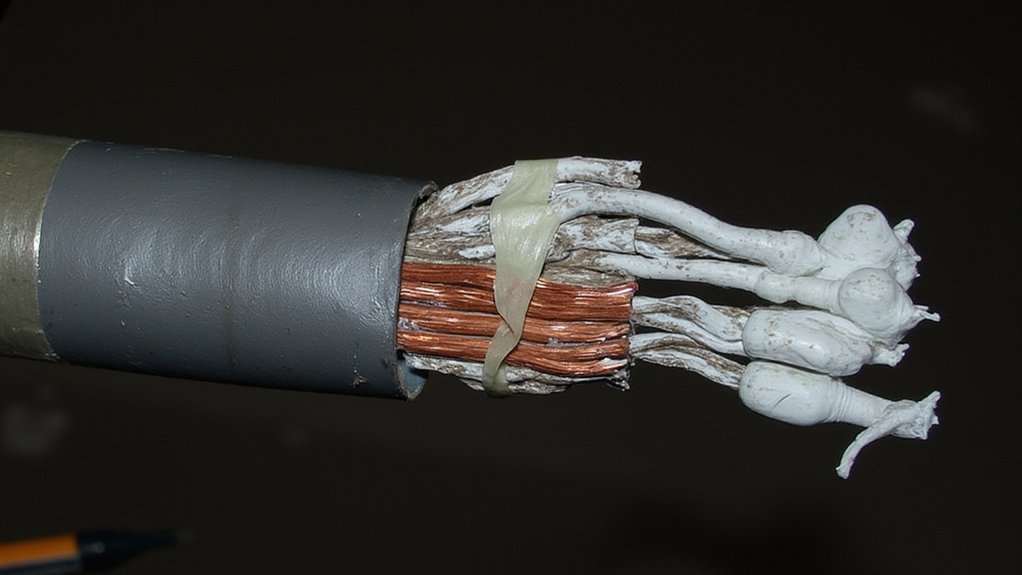

- Damaged Wire Cores

- Never attempt to repair broken internal wires

- Replace entire section with matching gauge wire

- Use UL-listed wire connectors for joins

“Remember, any repair that requires opening the wire’s insulation should be handled by a licensed electrician,” Martinez emphasizes.