You’ve probably used duct tape for countless household repairs, but when it comes to electrical work, this versatile tool isn’t your friend. Despite its strength and stickiness, duct tape’s rubber-based adhesive and polyethylene backing make it non-conductive – a fact that electrical engineer Mark Stevens confirms: “Duct tape provides zero electrical conductivity and can create dangerous situations when used with live wires.” Let’s examine why this matters for your safety.

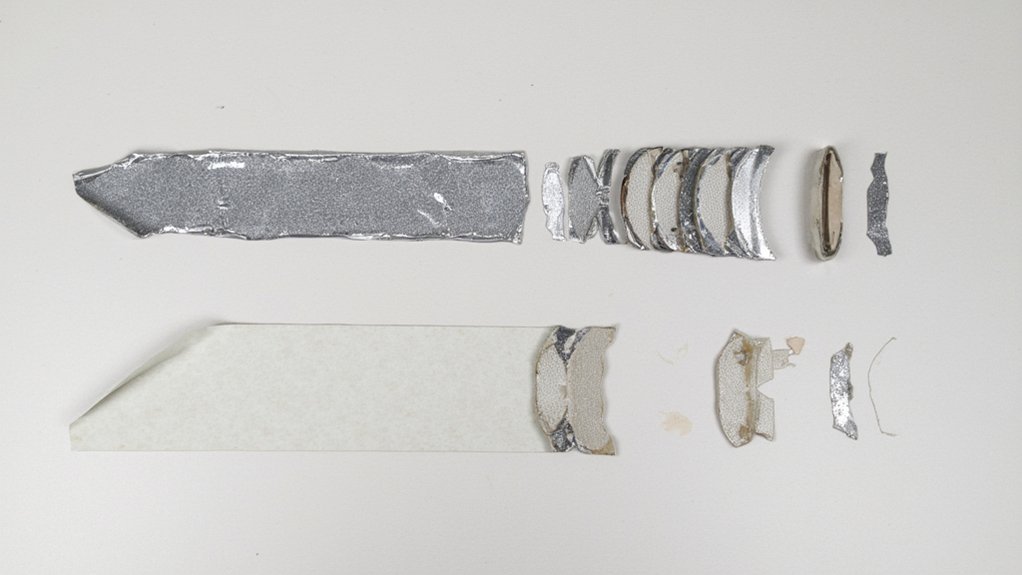

The Basic Composition of Duct Tape

Duct tape’s three-layer construction forms the foundation of its versatile nature. You’ll find these distinct layers working together to create this essential household tool:

- Outer Layer: A waterproof polyethylene coating that’s resistant to moisture and everyday wear

- Middle Layer: A mesh fabric grid made from cotton or polyester fibers that provides strength

- Bottom Layer: A rubber-based adhesive that creates a strong bond with surfaces

“The fabric reinforcement is what gives duct tape its characteristic tear-straight property,” explains materials engineer Dr. Sarah Chen. You can easily identify these layers by carefully peeling back a corner of the tape. The thickness varies by brand, but standard duct tape measures approximately 11-13 mils (0.011-0.013 inches) in total thickness, with the adhesive layer accounting for about 40% of this measurement.

Understanding Electrical Conductivity

When it comes to understanding electrical conductivity, you’ll need to grasp how materials either allow or resist the flow of electrical current through them. “Conductivity is measured in siemens per meter (S/m), with metals typically having values above 10^6 S/m,” explains electrical engineer Dr. James Chen.

Materials fall into three main categories based on their conductivity:

- Conductors (like copper and aluminum): Above 10^6 S/m

- Semiconductors (like silicon): Between 10^-6 and 10^4 S/m

- Insulators (like rubber and plastic): Below 10^-8 S/m

You’ll find that temperature affects conductivity – most materials become less conductive as they get hotter. This relationship helps explain why electrical components often need cooling systems to maintain peak performance.

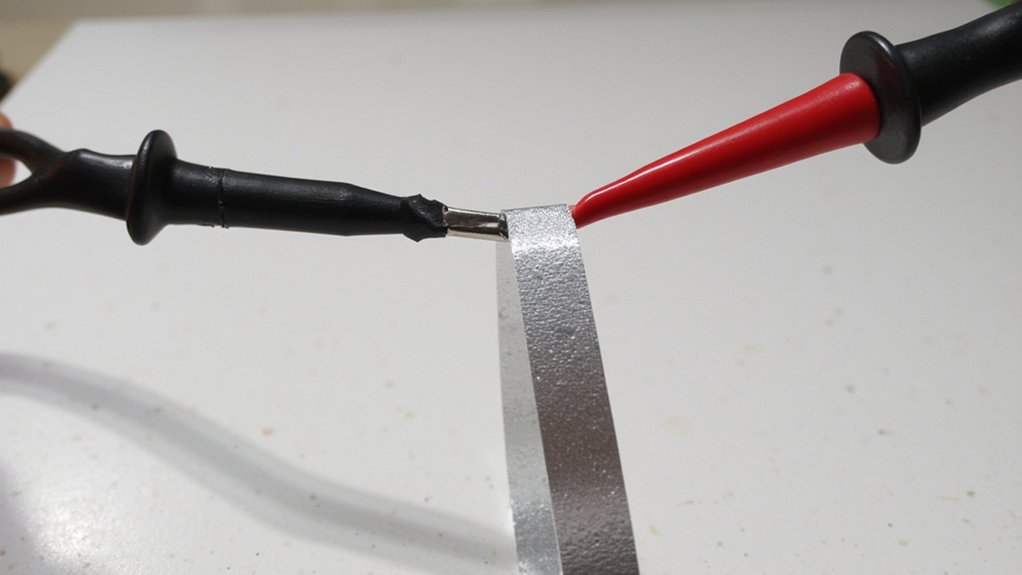

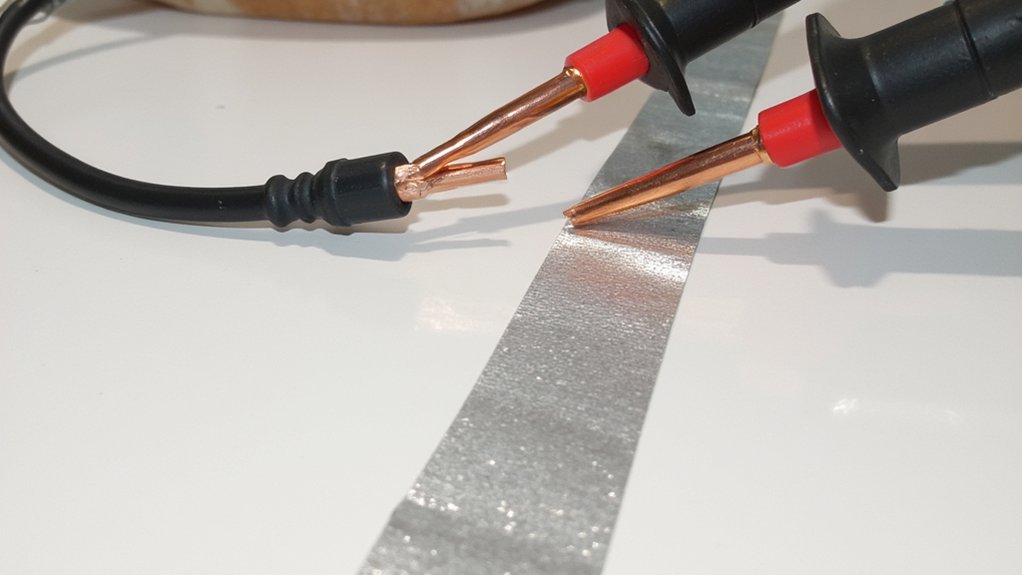

Testing Duct Tape’s Conductive Properties

Standard testing methods from electrical engineering can help us determine where duct tape falls on the conductivity spectrum. “A basic multimeter test across different brands and varieties of duct tape typically shows minimal conductivity readings,” notes electrical safety inspector Mark Thompson.

To test duct tape’s conductivity yourself, you’ll need:

- A digital multimeter

- Several strips of duct tape

- Clean metal contacts

Testing Steps:

- Set your multimeter to resistance mode (ohms)

- Place two metal contacts 6 inches apart

- Apply duct tape between contacts

- Take readings at various points

“Even with pressure applied, most duct tapes register infinite resistance,” explains Thompson. “The adhesive and backing materials are specifically designed to be non-conductive for safety reasons.”

Safety Risks and Electrical Applications

Despite its versatility around the house, you should never use duct tape as a substitute for proper electrical insulation or repairs. “Using duct tape near electrical components creates serious shock and fire hazards,” warns certified electrician James Miller, who emphasizes that the adhesive can degrade when exposed to heat from wiring.

Here’s why you’ll want to avoid using duct tape for electrical work:

- The adhesive breaks down at temperatures above 140°F

- Moisture can seep through the tape’s porous backing

- The metallic surface might conduct electricity in some varieties

- It’s not UL-listed for electrical applications

Instead, you should always use proper electrical tape or heat-shrink tubing rated for your specific voltage requirements. These materials are designed to withstand electrical current and provide reliable insulation for years of safe operation.

Alternative Tapes for Electrical Work

Several electrical-rated tapes offer safe and reliable alternatives to duct tape for your wiring projects. Here are the top options you’ll want to evaluate:

- Electrical Tape: UL-listed vinyl tape rated for up to 600V, available in multiple colors for wire identification

- Self-Fusing Silicone Tape: Creates a waterproof seal and insulates up to 400V

- Heat Shrink Tape: Contracts when heated, providing professional-grade wire protection

- Glass Cloth Tape: Withstands temperatures up to 300°F, ideal for high-heat applications

“Always choose tape that meets UL safety standards and voltage requirements for your specific application,” advises Master Electrician Jim Reynolds. You’ll find these tapes at any hardware store, typically priced between $3-15 per roll. For best results, wrap conductors with 50% overlap and extend coverage 1/2 inch beyond connection points.

Best Practices for Emergency Repairs

When you’re faced with an urgent electrical issue, temporary repairs using proper safety protocols can help prevent hazards until professional help arrives.

Emergency Repair Safety Steps:

- Turn off power at the circuit breaker

- Use a voltage tester to confirm no electricity is present

- Keep proper electrical tape on hand – never substitute duct tape

- Work in a well-lit, dry area

“Even in emergencies, following basic safety procedures can prevent serious injury or fire,” says Master Electrician Tom Wilson. If you’re dealing with exposed wires:

- Wrap each wire individually with electrical tape

- Keep wrapped wires separated by at least 1/2 inch

- Apply a second layer of tape for extra protection

- Schedule professional repairs within 24 hours

Remember: These steps are temporary solutions only. Don’t delay getting expert help.