When it comes to electrical work, the tape you choose can mean the difference between safety and disaster. You might be tempted to reach for that sturdy roll of Gorilla Tape in your toolbox, especially given its reputation for strength and durability. However, as electrical expert John Martinez warns, “Using non-rated tape for electrical connections is like playing with fire.” The critical differences between these tapes – and why one could put your home at risk – involve more than just their adhesive properties.

Understanding Electrical Tape Properties

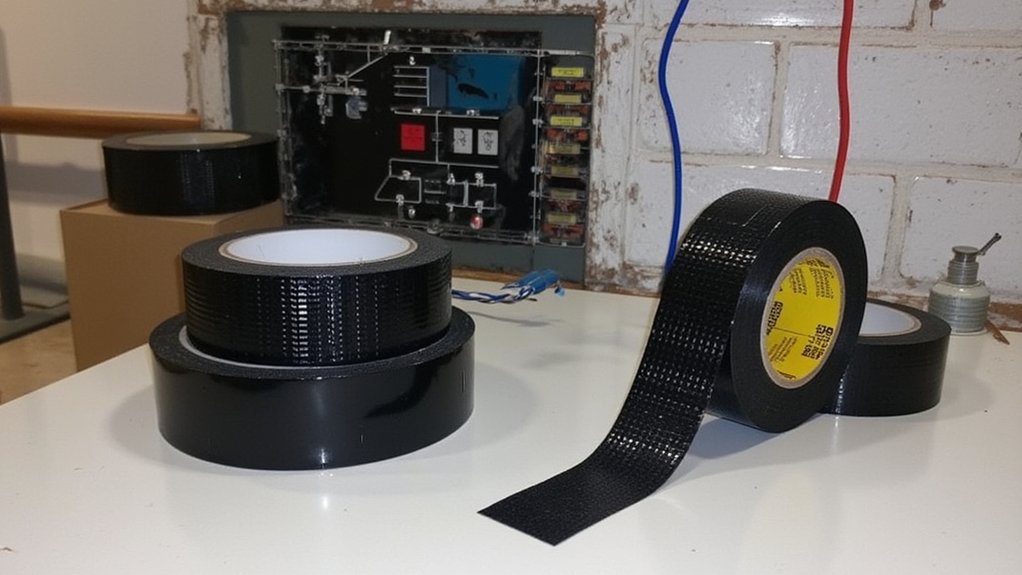

When it comes to electrical safety, electrical tape serves as an essential insulating material specifically designed for working with electrical wires and connections. Here’s what makes electrical tape unique:

- UL-listed for up to 600 volts

- Heat resistant up to 176°F (80°C)

- Stretches and conforms to irregular shapes

- Self-adhesive properties that prevent unwinding

- Non-conductive PVC backing

“Electrical tape’s specialized construction provides vital protection against shorts and electrical hazards,” explains master electrician John Martinez. You’ll find that quality electrical tape maintains its flexibility and adhesion even in extreme temperatures, while its elastic properties allow for tight wrapping around wire connections. The tape’s thickness (typically 7 mils) provides reliable insulation without adding bulk, and it’s designed to resist moisture, acids, and UV exposure.

Key Features of Gorilla Tape

Gorilla Tape stands apart from standard duct tapes through its triple-layer construction and aggressive adhesive formula. The tape features a reinforced backing that’s twice as thick as traditional duct tape, making it extremely durable in tough conditions.

Key Components:

- Weather-resistant shell

- Double-thick adhesive layer

- Reinforced fabric backing

- 3-inch wide standard roll size

“The tape’s aggressive adhesive formula allows it to grip onto rough and uneven surfaces that most tapes can’t handle,” explains contractor Mike Reynolds. You’ll find it sticks well to wood, stone, stucco, and brick – even in wet conditions. The tape’s tight weave creates a water-resistant barrier that won’t break down when exposed to moisture or UV rays, though it’s not designed for electrical insulation.

Safety Risks and Hazards

Despite its impressive grip and durability, you shouldn’t use Gorilla Tape for electrical applications due to serious safety concerns. “The adhesive and backing materials aren’t rated for electrical insulation, which creates significant fire and shock risks,” warns licensed electrician James Martinez.

Key safety hazards include:

- No UL certification for electrical use

- Non-resistant to high temperatures (melts at 200°F)

- Lacks proper voltage rating

- Cannot prevent electrical arcing

“Even in low-voltage situations, Gorilla Tape’s rubber-based adhesive can deteriorate within 3-6 months when exposed to electrical current,” explains Martinez. You’re putting yourself at risk of:

- Electric shock (up to 120V in household circuits)

- Short circuits leading to fires

- Conductor exposure due to adhesive breakdown

- Code violations that could void insurance coverage

Temperature and Environmental Factors

Although Gorilla Tape performs well in moderate conditions, its adhesive and backing materials start degrading rapidly in extreme temperatures and weather exposure. “The tape’s maximum temperature rating of 200°F means it won’t hold up in hot attics or near heat-producing equipment,” explains industrial adhesives specialist Dr. Greg Morton.

You’ll notice significant performance drops when using Gorilla Tape in environments above 150°F or below 20°F. In humid conditions above 80% relative humidity, the adhesive can begin to separate from the backing within 2-3 months. Unlike electrical tape, which maintains flexibility in cold weather, Gorilla Tape becomes stiff and may crack. When exposed to direct sunlight, UV radiation causes the tape to break down within 6-12 months, making it unsuitable for permanent outdoor electrical applications.

Proper Electrical Insulation Requirements

The electrical code requires specific insulation ratings that basic adhesive tapes can’t meet. “Every electrical connection needs UL-listed insulation rated for the voltage and environmental conditions,” states Master Electrician Jim Payton of the International Brotherhood of Electrical Workers.

Key electrical tape requirements include:

- Minimum 600V rating

- Heat resistance up to 176°F (80°C)

- Self-extinguishing properties

- Elastic recovery of 50%

- Insulation resistance of 100 megohms

You’ll need tape that meets these standards for:

- Wire splices and terminations

- Cable bundling and organization

- Temporary repairs until permanent solutions

- Low-voltage electronic projects

“Proper electrical tape creates a moisture-resistant seal that maintains consistent insulation properties over time,” explains Payton. “Non-electrical tapes like Gorilla Tape don’t provide adequate protection against electrical hazards.”

Alternative Tapes for Electrical Work

While standard electrical tape remains the safest choice for electrical work, several specialty tapes can serve as UL-approved alternatives in specific situations.

Consider these UL-listed options:

- Self-fusing silicone tape: Provides excellent insulation up to 400°F

- Rubber splicing tape: Offers moisture resistance and 600V rating

- High-temperature fiberglass tape: Withstands up to 600°F

“Never substitute general-purpose tapes like masking, duct, or Gorilla tape for electrical applications,” warns Master Electrician John Davis. “These lack proper voltage ratings and heat resistance.”

When selecting alternative tapes, you’ll need to verify:

- UL certification for electrical use

- Voltage rating (minimum 600V)

- Temperature rating (at least 176°F)

- Flame-retardant properties

- Weather and moisture resistance

Best Practices for Wire Protection

Proper wire protection involves several critical safety measures that you’ll need to implement before starting any electrical project.

Key Protection Steps:

- Use UL-listed electrical tape rated for 600V and 80°C minimum

- Wrap wires with 50% overlap, extending ½ inch past connection points

- Apply at least 3 layers for complete insulation coverage

“Never substitute non-electrical tapes for wire protection, as they lack proper temperature and voltage ratings,” warns Master Electrician John Davis.

Additional Safety Measures:

- Install appropriate junction boxes

- Use wire nuts rated for your wire gauge

- Maintain proper wire spacing (minimum 1.5 inches apart)

- Check connections for heat after 1 hour of use

Remember to inspect your wire protection every 6 months and replace damaged or degraded materials immediately.